Rolex Barrel Update for Calibers 1520 1530 1555 1556 1560 1570 1575

- Mike

- Nov 3, 2025

- 4 min read

Updated: Nov 18, 2025

The Rolex caliber 15xx movement is arguably the most iconic movement ever made (by any brand). It’s the heartbeat of our most beloved Rolex models during its 42 year run between 1957 to 1989. From the Submariner 5508, first introduced in 1957, to the Submariner 5513, discontinued in 1989, Rolex’s longest-running movement was the 15xx caliber.

One of the common weak spots on the Rolex cal.15xx are the two bore holes located directly above and bellow for the mainspring barrel. The lower bore hole is located on the main plate and while the upper bore hole is located on a removeable bridge used to secure the main spring barrel (barrel bridge). From the factory, a simple hole was machined into the main plate and bridge to allow the barrel to spin. Simple but not durable.

In hindsight, Rolex shouldn't have released the cal. 15xx without some sort of protection against the high pressure wear caused by main spring barrel. As a watch runs, the force of the barrel turning will (over time) destroy the upper and lower lower bore holes on main plate and barrel bridge. it’s not a matter of “if” but “when”.

Rolex did, however” later released an update to resolve this issue, thus, avoiding the need to replace the entire main plate and/or barrel bridge every time this occurred. We refer to this as the cal. 15xx" Barrel upper and lower" update. Specialty tooling is needed to retrofit the main plate and barrel bridge to accept a protective bush.

Later Releases

With the Rolex Caliber 3035—successor to the Cal. 1570—Rolex introduced a replaceable copper beryllium bushing (or sleeve) to protect the main plate and bridges from this type of wear. The downside of copper beryllium, is that it’s rather soft and will wear over time, but it’s easily replaced when needed.

On the Rolex Caliber 3135, the successor to the Cal. 3035 Rolex opted for a ruby bush (sleeve) to protect the main plate and bridges. This is one of the reasons the jewel count went from 27 jewels on the caliber 3035 to 31 jewels on the caliber 3135. With a MOHS hardness of 9, just below diamond, these ruby bushes are harder than the steel, so when it’s wheel with steel pivots vs ruby, the ruby wins. Essentially this Rolex throwing everything at this issue to resolve it once and for good.

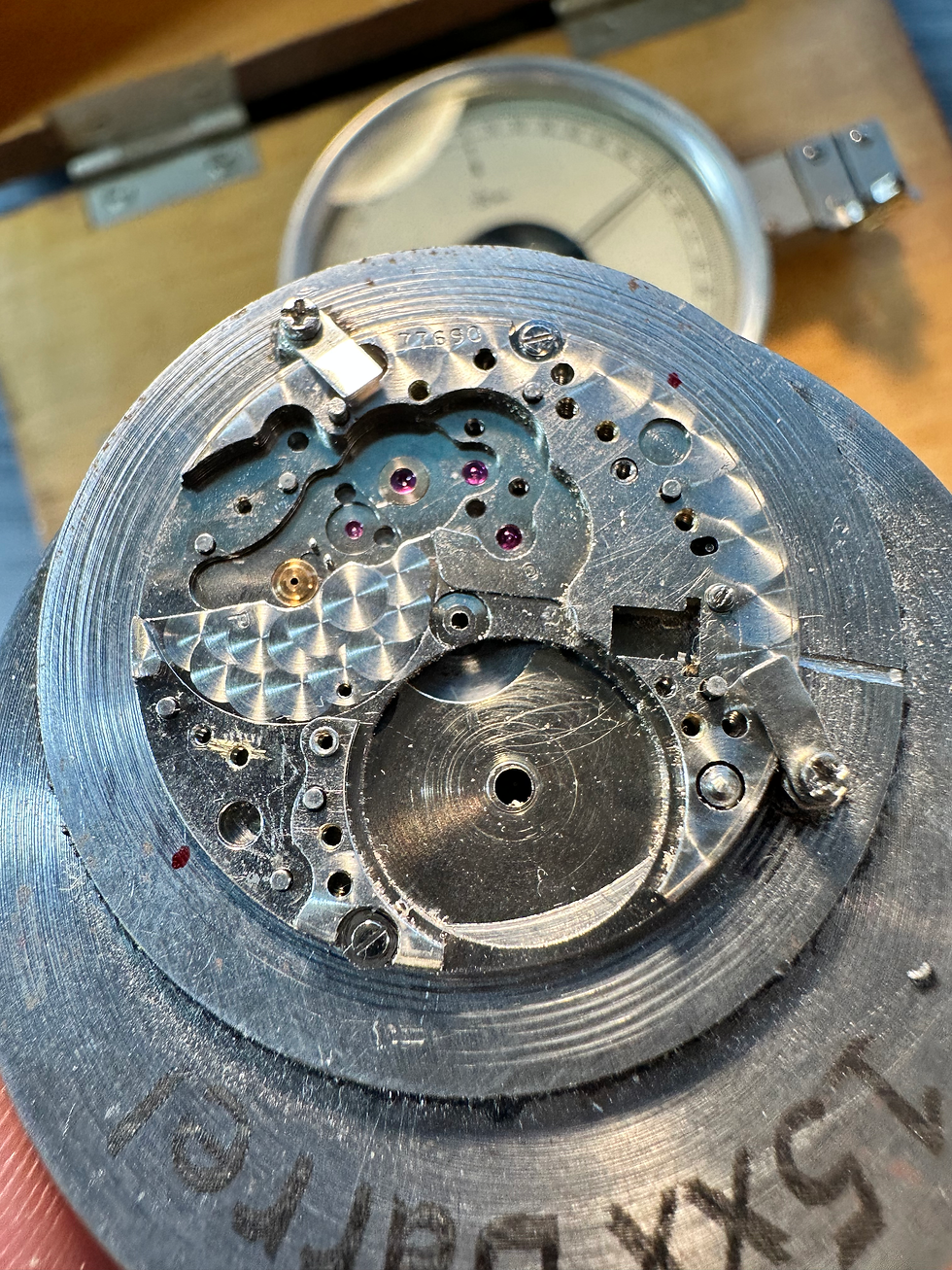

Precision machining using a watchmaker lathe

On a caliber 15xx to repair this properly we use a watchmaker lathe, a specialty chuck, and a centering scope that allows us to maintain the exact same center position as it came from the Rolex factory. Keeping the exact center point for both the upper and lower holes is vital. If the upper and lower hole are not perfectly aligned one above another, it can force the barrel to tilt, permanently. Not good.

Horror stories- Installing a bush without the proper tools

It makes us cringe when we see things like this. Right idea, poor execution. We advise against installing bushes without the proper high precision tooling. These crude methods just creates more work for someone else down the line.

We have seen shops enlarge the bore hole by hand. Sure it makes the hole large enough to accept a bush, but it was done without any regard to where "true" center should be. Sometimes this can work, until it doesn't.

After machining:

With proper tooling, the main plate is machined to create a precise opening so a bush can be installed. We prefer the longer lasting ruby jewel option over copper beryllium for this repair. This is what barrel bridge looks like with a new ruby jewel installed. If you noticed that it resembles the design of the cal. 3135 you are correct. The barrel arbor now only makes direct contact with the two rubies (top and bottom) rather than the much softer brass main plate or barrel bridge. I will be spouting daisies well before these bushes will need replacing. Bob’s your uncle, Rolex 15xx barrel bush update is now complete!